Lithosan Examined Current Production Approaches On-Site at the Heidelberg Wiesloch Technology Center

We were pleased to participate in the factory tour and technical presentation program held at the production and technology center in Wiesloch, Germany, organized by BASEV (Printing Industry Education Foundation) as representatives of the BASEV Board of Directors and Lithosan. This program, which also included members of the BASEV Board of Directors, Trustees, and academics from Marmara University, provided an extremely productive environment for knowledge sharing among industry professionals.

Heidelberger Druckmaschinen AG Board Member Dr. David Schmedding, Global Marketing Director Elke Steinbach, and Executive Assistant Technology and Sales Manager Lara Kühn welcomed all visitors individually. The program, hosted by Heidelberg, was conducted with the participation of Heidelberg Turkey General Manager Selkut Engin and Offset Printing Product Manager Kutay Ercan.

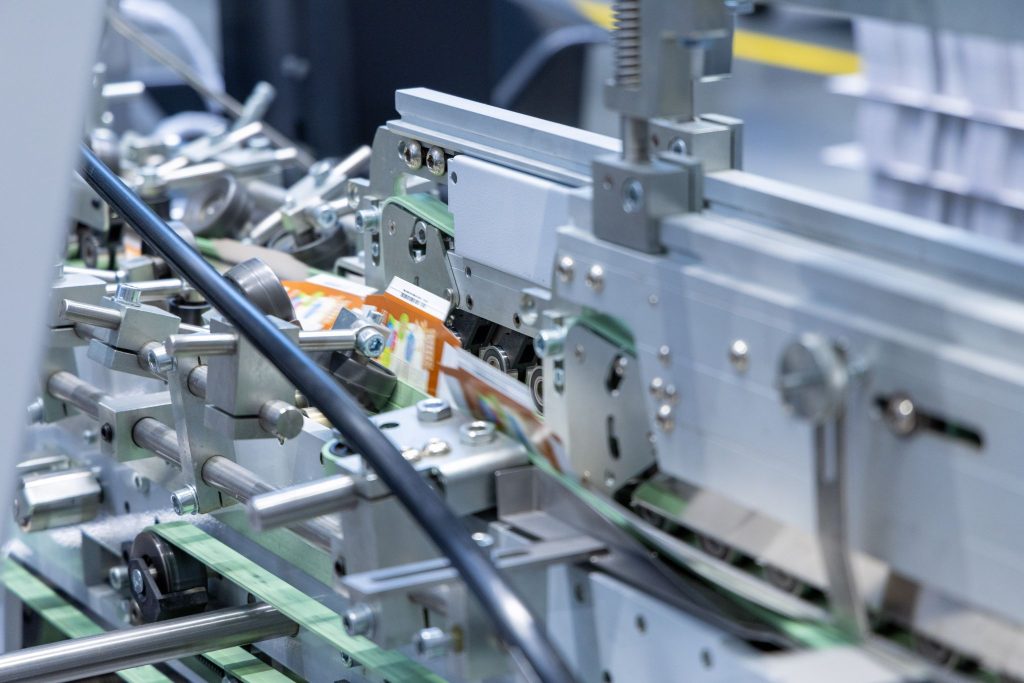

Throughout the day, interactive presentations, production demonstrations, and technical sharing sessions provided participants with the opportunity to gain both theoretical and practical knowledge. During the visit, advanced production systems such as the Speedmaster CX 104, Gallus One, and Diana Pharma, along with the Prinect software infrastructure, were examined in detail.

Information shared by Nick Trabold, Head of Global Service Operations and Print Media Center in Heidelberg, and Janine Schneider, Media Designer and Prinect Application Specialist, provided participants with important perspectives on process management, automation, and digitalization.

The lunch meetings held after the production demos provided valuable networking opportunities.

During the visit, it was observed firsthand how accessible practical knowledge of printing technologies is thanks to Heidelberg's globally established Print Media Center and showroom network. Spanning from Wiesloch, Germany, to Atlanta, USA, and from Tokyo to Shanghai, this structure offers a robust ecosystem that supports industry knowledge sharing through customer demos, application experiences, and solutions tailored to regional needs.

At Lithosan, we have been choosing Heidelberg technologies for our production infrastructure for many years, and we see this partnership as an important part of our sustainable quality approach. This visit was very beneficial for us in terms of re-evaluating the systems we currently use in the production field, following technological developments on site, and refreshing our knowledge.

We would like to thank the entire Heidelberg team for their gracious hospitality and valuable insights. We will continue to monitor the future-oriented printing technologies on site and maintain our investments in line with this vision.