The Future of the Printing Industry: Shaped by Digitalization, Collaboration, and Continuous Development

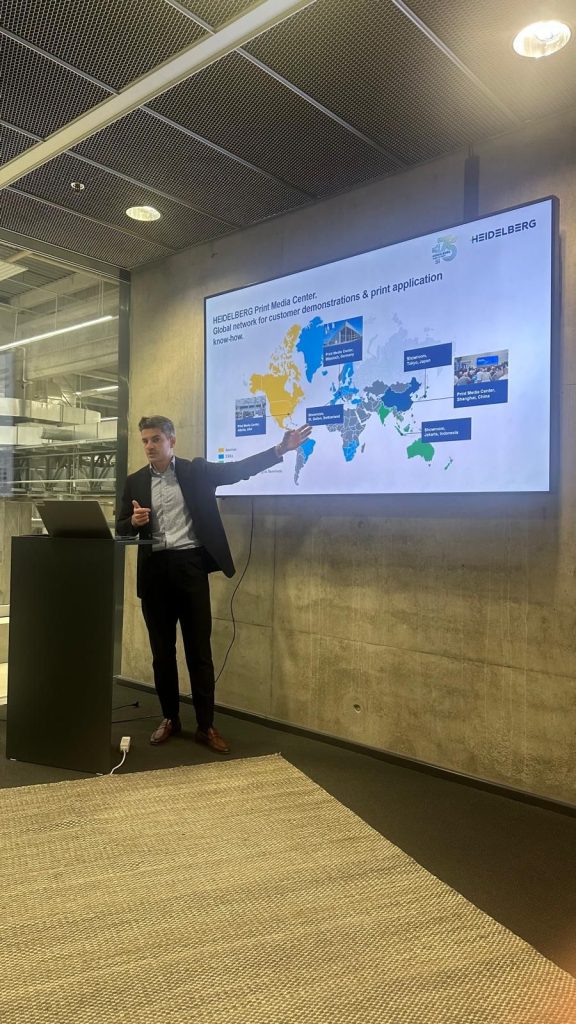

Heidelberger Druckmaschinen AG's global impact is evident not only in technology but also in the sharing of knowledge and experience. We gained access to practical knowledge about printing technologies through visits to the Print Media Center and showroom. Heidelberg's strategic invitation is an exemplary model that combines its global vision with printing and packaging experts.

🌍 This powerful network stretching from Wiesloch, Germany to Atlanta, USA, and from Tokyo to Shanghai:

✔ Customer demos

✔ Application experiences

✔ Solutions tailored to regional needs

by bringing together the industry and knowledge.

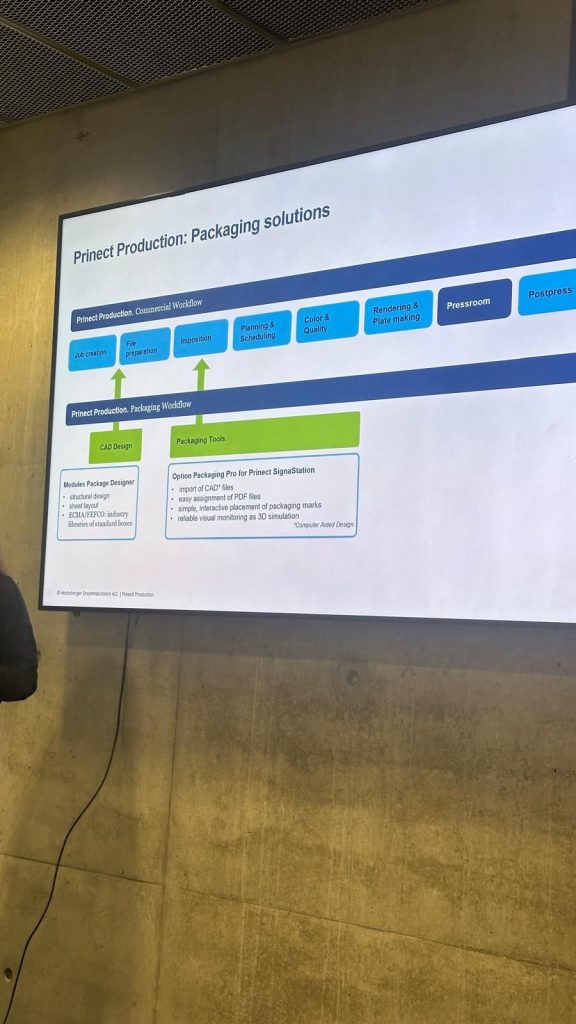

📊 Digital Transformation in the Printing Industry: Prinect

The Prinect system developed by Heidelberg is an innovative workflow solution that digitizes and integrates printing processes.

🔹 Time savings and error reduction thanks to smart automation

🔹 An integrated structure that manages the entire process on a single platform

🔹 Online access and sustainable use with a subscription model

🔹 High-level quality in color management and print standardization

🎯 Commercial Workflow

– Job creation

– File preparation

– Layout (imposition)

– Planning and scheduling

– Color and quality control

– Render and mold production

– Printing process

– Post-press operations

This structure represents a standard workflow.

📦 Packaging Workflow

Since packaging production is more complex and has specific requirements, the workflow is divided into two main components:

1. CAD Design

– Structural design

– Page layout

– ECMA/FEFCO industry standards

– Standard box libraries

2. Packaging Tools

– Importing CAD files

– Easy alignment of PDF content

– Interactive placement of packaging labels

– 3D simulation for visual control

This structure provides specialized tools and modules to ensure both technical accuracy and visual quality in the packaging printing process.

During the visit, the differences between commercial and packaging printing workflows in the Prinect Production system were discussed comparatively. In commercial printing, classic job preparation, assembly, planning, color management, and production steps stand out, while in packaging printing, additional processes such as CAD-based design, ECMA/FEFCO standards, PDF content alignment, interactive packaging markings, and 3D simulation were observed to make the workflow more detailed. This structure offers significant advantages in terms of both technical accuracy and visual quality in packaging production.

We had the opportunity to experience firsthand once again that digital transformation in the printing industry is advancing not only through machinery but also through integrated software infrastructures, automation, and data management. At Lithosan, we find such technical sharing and international knowledge exchange extremely valuable in line with our approach that addresses productivity, quality, and sustainability in production within the same framework.